|

CRISTAL WMS

|

|

Picking > Adhoc

This page is under construction. Its contents.will change as and when the page is edited.

![]()

What is Adhoc Picking?

Concept

In Normal Picking, a Sales Order with a list of items and their required qtys are first created and released to the warehouse. The WMS generates a pick list for the sales order item, and the warehouse operator proceeds to pick the required items from the specified locations in the pick list. The picked items are then despatched to the customer.

In Adhoc Picking, there is no preliminary list of items provided by the client. Instead, the client comes down to the warehouse, and then simply picks off items from their storage pallets while walking around the storage locations. The picked items are then processed as Adhoc Picked items, and a Sales Order will be created off the picked items.

This is akin to shopping inside a supermarket wheeling a shopping trolley, picking grocery items off the shelves and putting them into the trolley, and then finally going to the cashier and checking the items out of the supermarket.

Mobile Location

When items are adhoc picked from the storage location, the qty is deducted immediately from the storage location's inventory.

The qty is added to the "shopping trolley" location, which is designated as a Mobile Location.

In the WMS, it is necessary to pre-create some Mobile Locations before the RF Adhoc Picking program can be used. As items are being "adhoc picked", the adhoc picked items will be transferred into the designated mobile location. When the adhoc picking is completed, the RF Adhoc Picking program will create the Sales Order detail records for all items that have been transferred into the designated mobile location.

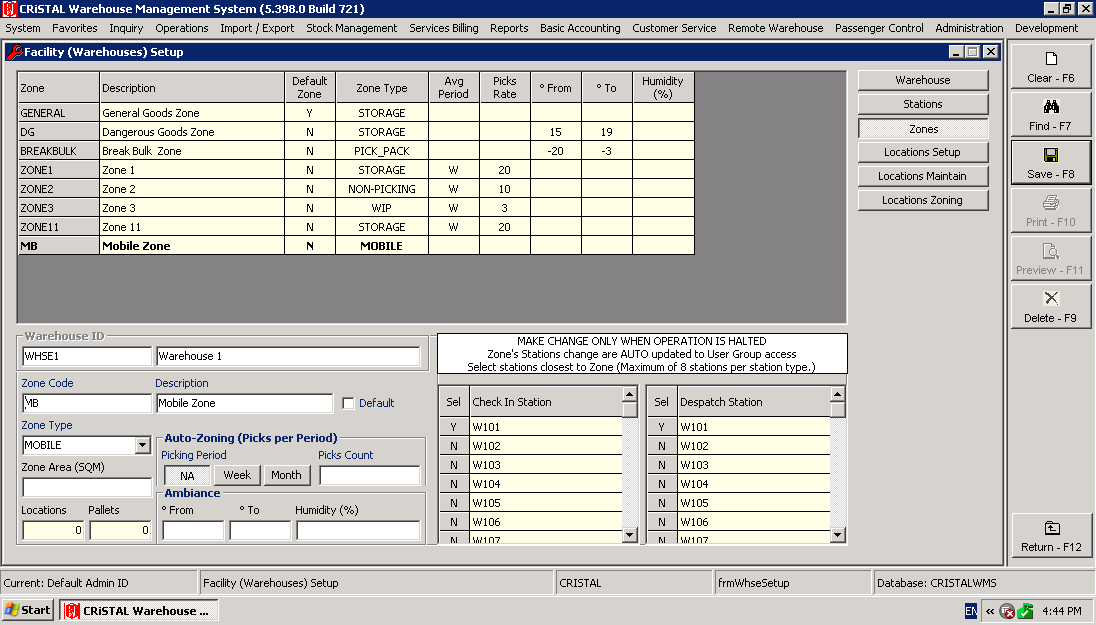

To create Mobile Locations, at least one zone in the warehouse must be created with the zone type "MOBILE":

In the above example, the zone "MB" has been created with zone type "MOBILE".

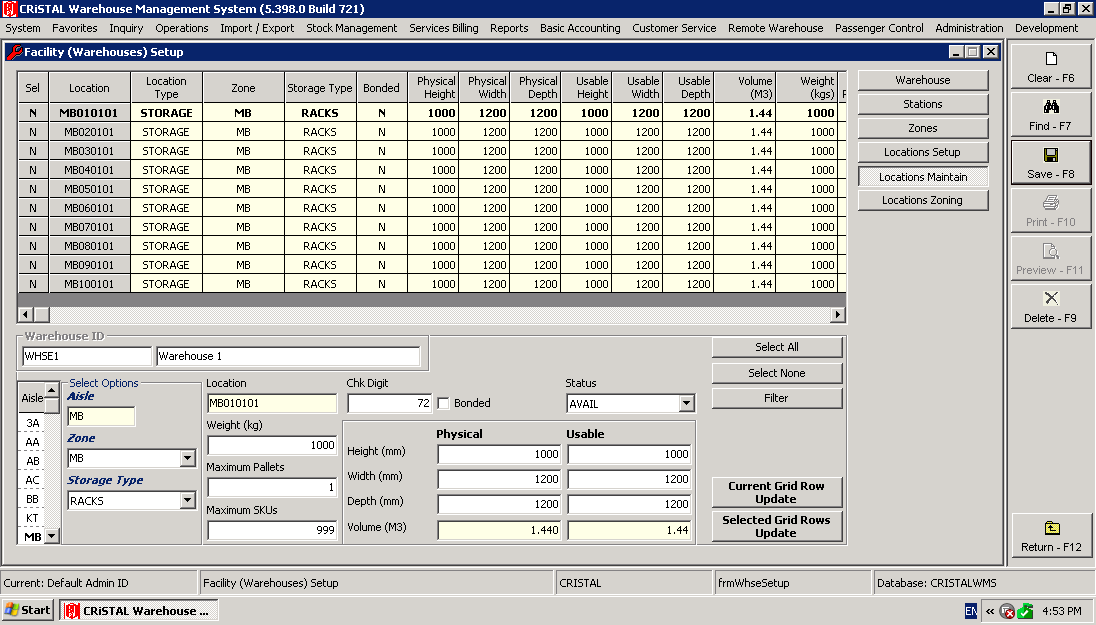

Then, at least one or more locations must be created in the "MB" zone:

In the above example, 10 locations have been created in the "MB" zone. This allows a maximum of 10 adhoc pick operations to be processed by 10 different operators concurrently. A warehouse needs a minimum of one Mobile Location to perform Adhoc Picking.

Header Tab

Related Resources