|

CRISTAL WMS

|

|

Incoming

Incoming covers goods entering the warehouse. This is covered by 2 menus:

- The Receiving programs allow users to

check-in goods and load them on to pallets. Once a pallet is

fully loaded, the pallet can be "closed" for putaway.

- The Putaway program is then used by the

putaway operator to record the actual location that the pallet

is putaway to.

Click on the hyperlinks to go to the full description of each menu option.

Program Permissions

An operator must be assigned various privileges to be able to run the 2 programs.

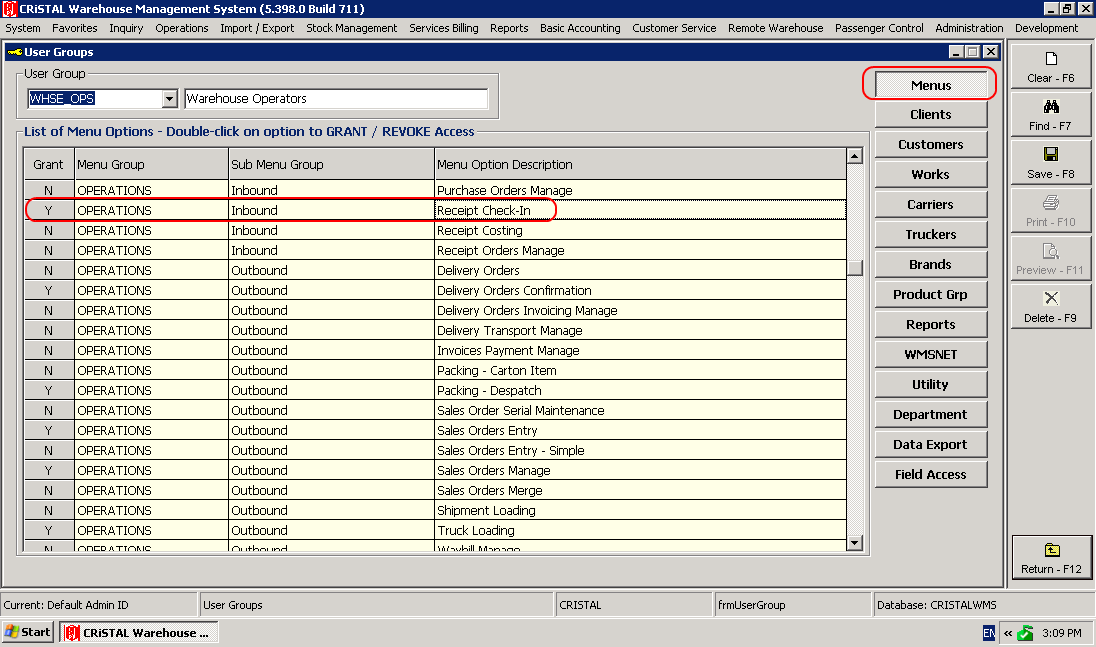

To run the Receiving program, the operator must be granted access to the Menus > OPERATIONS > Inbound > Receipt Check-In menu option.

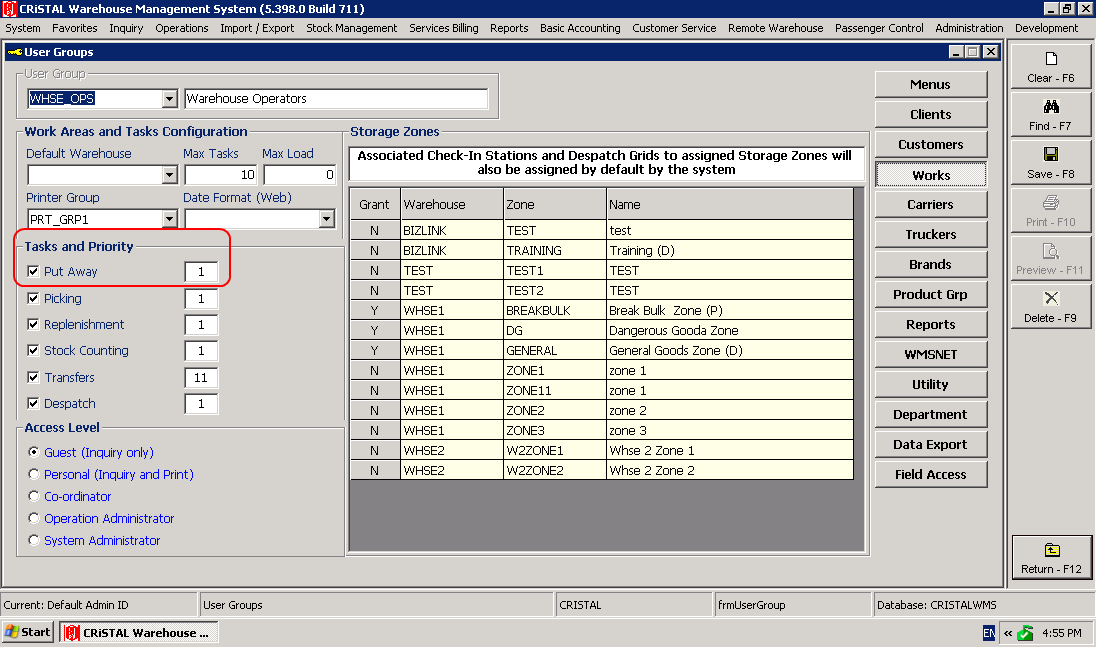

To run the Putaway program, the operator must be granted access to the "Put Away" task in the User Groups > Works > Tasks and Priority tab:

The User Groups > Works tab is also used to configure the warehouse areas that the operator is permitted to work in. A user who has the privilege to run the Putaway program, but who has no privilege to work in a particular zone, will not be allowed to perform putaways into storage locations in the forbidden zone.

Pallet Handling

Pallet Numbers

In the WMS RF programs, all goods that are received in the warehouse must be placed on a pallet before they can be checked in. All inventory records must be stored with a "Pallet Number" inside the database.

Virtual Pallets

However, the pallet media that is used physically in the warehouse may not have any identification number. Regardless, the WMS still requires that stocks be handled using the Pallet Number. Even if a location is merely a small tote box, the WMS assumes that the contents in the tote box are on a "virtual pallet" that is identifiable by its Pallet Number.

Merging Pallets

If a storage location is configured to hold only 1 pallet, then only 1 Pallet Number can be associated with the storage location at any time.

If a pallet is putaway or relocated to a "max 1-pallet" location, and this location already contains an existing Pallet Number, the WMS will move the contents from the putaway/relocating pallet into the existing pallet. After the merger, only the Pallet Number of the pallet that was in the location originally will still remain in the system. The Pallet Number of the putaway/relocating pallet will be cleared from the system.

Types of Receipts

Advanced Shipment Notice - ASN

When goods are sent to the warehouse, an advanced notice can be sent by the client to the warehouse a few days/weeks before the shipment. If this ASN information is keyed into the WMS system before hand, on the actual day when the goods arrived at the warehouse, the RF Receiving program can use this ASN record to check in the physical goods.

This kind of receipts, where the check-in items and qty are validated against an ASN record, are known as ASN Receipts.

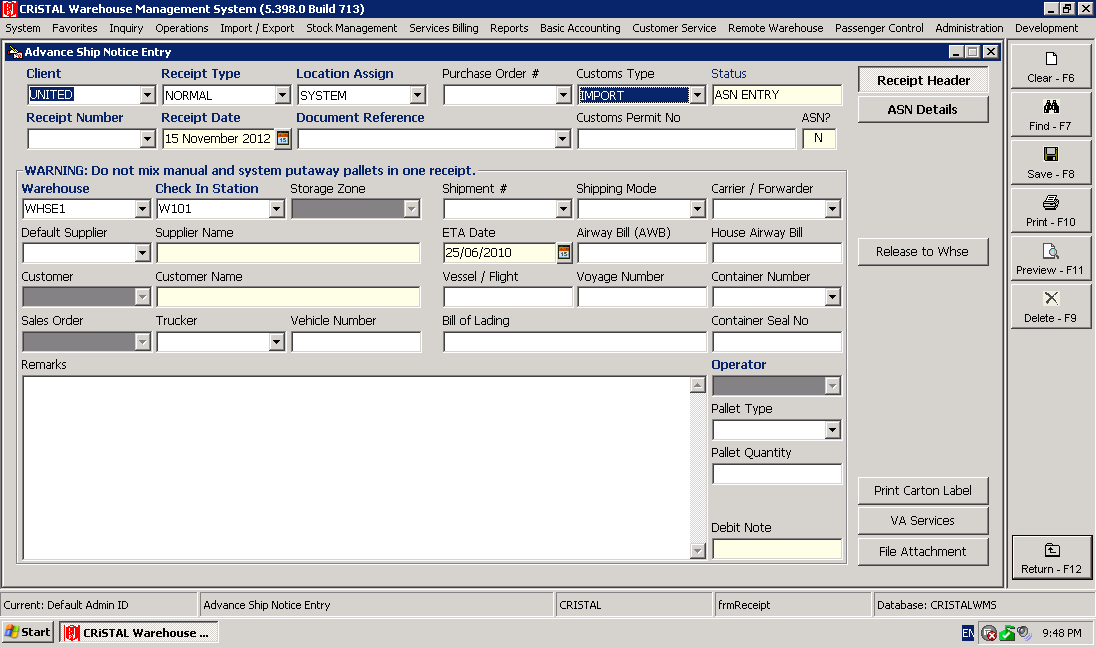

ASN Receipts must always be created from the Desktop WMS using the Operations > Inbound > Advance Ship Notice Entry program:

Blind Receipts

The RF Receving program can also be used to check-in items that arrive at the warehouse without any ASN. Receipts without ASN are known as Blind Receipts.

Returns Receipts

Normally, goods that are checked in to the warehouse are assumed to be Normal or Fresh goods. Fresh goods are always picked using a FIFO (First In - First Out) policy.

When picked goods that have been previously despatched from the warehouse are returned to the warehouse (e.g. cancelled by customer, unable to send to delivery address etc), these returned goods need to be check into the warehouse again. For such returned items, we must indicate that we are processing a Returns Receipts.

Crossdock Receipts

Sometimes, goods that are received at the warehouse can be despatched immediately. The goods that have been checked in and which are currently in the receiving sation do not need to be putaway into storage, and can immediately be used for picking.

There are 2 types of crossdock goods:

- In the first type, the goods that have just arrived at

the warehouse can be despatched as is (no repacking required) to

the customer at the delivery point. Such goods are also known as

Dropship goods, because they can be dropped at the warehouse and

shipped out immediately as is. CRISTAL WMS uses the code

"XDOCK-D" to refer to such crossdock goods.

- In the second type, the goods that have been received at the

warehouse needs to be repacked into different packing units. For

these goods, we have to Break-Bulk the pallets that had been

sent to the warehouse, so that we can repackage the goods into

smaller quantities for delivery to the customer. CRISTAL WMS

uses the code "XDOCK-B" to refer to such crossdock goods.

Note that for Crossdock Receipts, the RF Receiving program will not propose a putaway location.

Transaction Recording Modes

The RF program allows goods to be recorded by:

Qty

In this mode, the operator must specify the:

- Item No

- UOM

- UOM qty

If the operator enters an SKU for Item No, the system will automatically translate the SKU to the Item No. The reason for this is that the Qty mode allows the user to check in by "PALLET" or "CARTON" units, and the UOM must be explicitly specified.

Transactions by Qty is usually employed for checking in goods that do not have SKU barcodes (such as UPCs, EANs, or GS1).

SKU

For SKU transactions, each SKU scanned is interpreted as:

- 1 unit of the packing UOM of the Item No

Transactions by SKU is usually employed with goods such as apparel, shoes etc where each incoming pallet contains a mixture of goods with different SKUs.

For example, a shoe box will have an SKU identifiying the Item No, the shoe size, shoe color, and shoe style. The incoming pallet may contain 100 shoe boxes, but only say 20 unique SKU variations (with varying qtys of each SKU). By simply scanning each SKU in the RF Receiving program, the RF program can be used to tally the actual qtys of each SKU automatically.

Serial No

For Serial No transactions, the user simply scans in the serial number to check in the serialised item. The serial number will identify the Item No that is being transacted.

However, the above will only be possible if a list comprising of serial numbers and their corresponding Item No has been imported into the database earlier. Sometimes, the client may not possess such a list to give to the warehouse prior to the shipment of goods arriving at the warehouse. In such cases, the client may require that the Serial No/Item No association be created at the point of check in by the RF program.

Carton No

For Carton No transactions, the user scans in the carton number to check in the contents of the carton. The carton number identifies the Item No and the quantity of the item in the carton.

Like serial number scanning, carton number scanning is only possible if a list of carton numbers and the carton contents have been imported into the database earlier. Sometimes, such a list may not be available, and the client may require that the Carton No/carton contents be created at the point of check in by the RF program.

Cartons can contain serialised or non-serialised items.

Outer Cartons and Inner Cartons

Cartons can also contain cartons of items. The larger carton is known as the Outer Carton, and is identified with an Outer Carton No. The smaller carton containing the items is known as the Inner Carton, and is identified with an Inner Carton No.

Basically, a normal carton containing items is identified by the Carton No. However, once this carton of items is packed into another carton, their carton numbers become respectively the Inner Carton No and the Outer Carton No.

Once an Inner Carton has been packed inside an Outer Carton, the Carton No now refers to the Outer Carton No. When transacting by the Carton No (ie. the Outer Carton No), the entire contents of all the inner cartons in this outer carton will be transacted. Also, it will no longer be possible to transact using the Inner Carton No. If you wish to transact an Inner Carton No, you must first Unpack the inner carton from the outer carton. Once unpacked, the Inner Carton No can then be transacted as the carton number.

Status Codes

Stock Status

- DATA ENTRY

When goods are still being added to a receiving pallet at the check in station, the goods on the receiving pallet will have a "DATA ENTRY" status.

- CHECKIN

Once the pallet is full, the check in operator must Close the pallet to indicate that the pallet has been checked in and is ready for putaway. The goods on the pallet will now be changed to "CHECKIN" status.

- AVAIL

Once the pallet has been putaway into a storage location, the goods on the pallet will be changed to "AVAIL" status. Only goods with "AVAIL" status can be picked for sales order fulfillment.

Receipt Header Status

- ASN ENTRY

When a receipt header is in "ASN ENTRY" status, it means that the ASN is still being modified and has not been released for receiving.

- DATA ENTRY

For ASNs, only receipt headers that are in "DATA ENTRY" status can be opened for receiving.

For Blind Receipts, the receipt header record created by the RF Receiving program is always created in "DATA ENTRY" status.

- PUTAWAY

After the first pallet has been completed (checked in) and is now pending putaway, the receipt header will be changed to "PUTAWAY".

(Note: receipt headers that are in "PUTAWAY" status can also be opened for receiving new goods.)

- CLOSED

For receipts with ASN, after the final pallet of goods has been completed (checked in), the receipt header will be changed to "CLOSED" instead of "PUTAWAY". Note that there may still be pallets pending putaway when the ASN receipt header is changed to "CLOSED".

Once the receipt header is changed to "CLOSED" status, the RF Receiving program will not allow new items to be checked in under the Receipt No.

For Blind Receipts (receipts without ASN), the RF Receiving program will not be able to determine whether all items have already been checked in. As such, the user must manually Close the receipt header.

- CANCELLED

For cancelled receipts.

ASN Line Status

- ASN ENTRY

The ASN line details can still be modified.

- WAITING

The ASN has been released for receiving. ASN line details can no longer be modified.

Receipt Line Status

- CLOSED

When a receipt detail line is created, it is always created with "CLOSED" status.

- CANCELLED

All receipt line status will be "CANCELLED" when the receipt header is cancelled.